What builder should do,

when prices of material rise

A year ago, a piece of welded curry net cost 400 crowns. Now you pay 4 times more. The price of a cubic meter of wood rose from 4,000 to 12,000 crowns in a few months, and this has an effect on invoices for beams, laths and ordinary OSB boards. The Czech construction industry has not experienced such an increase in prices. What about when you have a split order, sit down over budget and see that it's not working out for you? We asked the builders how they handle the unusual situation.

In good times, the profit from a construction contract should not fall below 20%. When there is no work, the owners of construction companies also take jobs where they keep zero. But no builder wants to subsidize the work out of his own pocket.

Builders who use Stavario repeatedly tell us that digitization has saved them exactly the percentages they are missing due to rising costs.

What's a construction company owner to do when rising material prices destroy approved budgets

To avoid this, he has 5 options:

- Inflation clause in the contract

- Second hand material

- Electronic material marketplaces for companies

- Increasing the price of a split order

- Digitization of the construction company

When paving a driveway, there is often leftover material that the builder offers for purchase.

1. Inflation clause in the contract

A clever formula in the contract that will allow the invoicing to increase if the price of the material increases. However, it has two problems:

- you have to solve it with the investor at the beginning of the contract

- and most builders never thought about it

Only multinational companies that build highways, dig railway tunnels or build new city districts usually have inflation clauses. Just a big construction business. Large companies already have experience with sudden price fluctuations on the market, and that's why they are safe in advance.

We, smaller builders, can take the current situation as inspiration for the future. Call your contract attorney and discuss how an inflation clause could be incorporated into future contracts.

2. Second hand material

When concrete blocks, outdoor paving or iron lintels are not available from traditional suppliers, try to ask for them elsewhere.

Prices for previously purchased but unused material can be orders of magnitude lower than in construction costs. But before you start browse online bazaars or ask private individuals in the area, discuss this option with the investor. And when you buy second-hand material, pay close attention to its quality.

3. Electronic material marketplaces for companies

A relative novelty that Czech builders do not use much yet. But it has tremendous potential. Electronic marketplaces work on a principle direct connection of the manufacturer, supplier and customer.

If the prices of aerated concrete blocks, screws, adhesive mortar or other materials have increased in the Czech Republic, this does not mean that they are the same in Poland or Lithuania. Suppliers place an offer on the website (what, quantity, where and for how much), you connect with them and order the material. All administration, including payment, will be provided by the electronic marketplace.

An example of such e-marketplace is a Czech-Polish project merxu.com, behind which is, among others, the founder of aukro.cz Václav Liška. The portal is only intended for companies, so you don't have to rummage through the offers of private individuals. The texts are automatically translated, thanks to which you can arrange everything in Czech, and there are often events on the portal such as free shipping or pay 30,000 and we'll give you 10,000 crowns back.

4. Increasing the price of a split order

Be very careful with this one. Investors read daily on the Internet how material prices are increasing. Therefore, they understand thatstrong, last year's budgets will not even cover the costs. Still, it's not their problem that you didn't stock up.

Banks or building societies react to the increase in material prices and increase the approved mortgages, but negotiating the price with the investor is complicated.

As the owner of a construction company, you have the opportunity to argue from a position of strength: "I'd rather pay the cancellation penalty than subsidize your construction from my own money. You won't be able to get a cheaper offer from the competition right now anyway, so let's come to an agreement." But really consider if it's worth it to you. A disgruntled investor can damage your reputation.

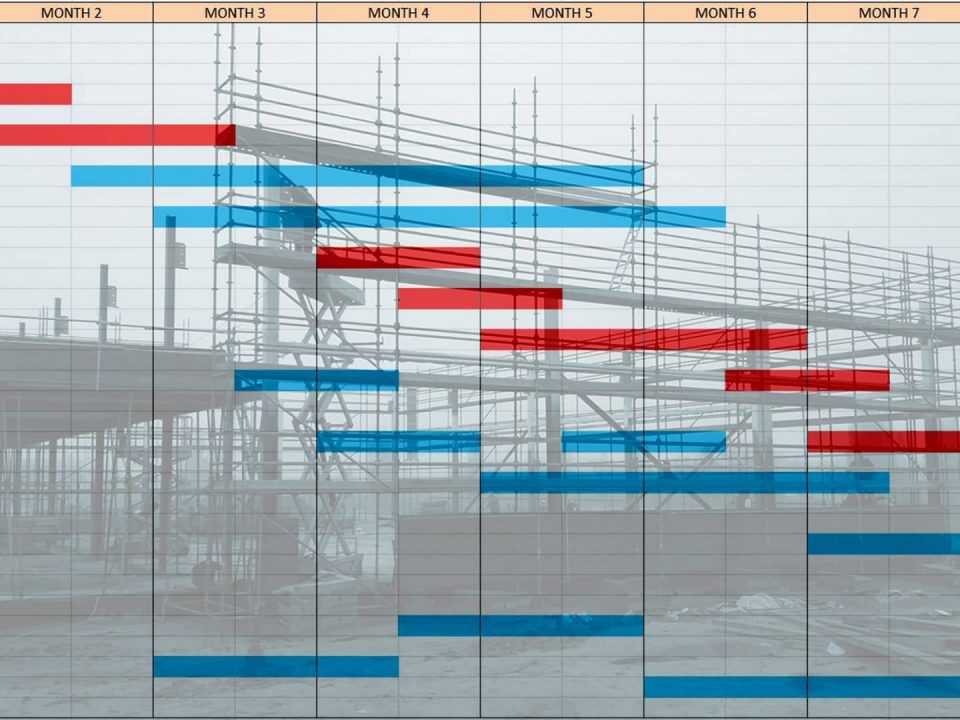

5. Digitization of the construction company

When a worker runs out of sand on a construction site at nine in the morning, he tries to call the construction manager. He has a meeting right now, so he doesn't pick up the phone. He calls back after lunch and finds that the building has been standing still for a few hours. He passes the request on to the preparer, who starts working on it. If it goes well, the sand is on the construction site the next day. But most of the time it doesn't go that well.

But you know it yourself. Downtime, inefficiency, time spent figuring out alternative work, stress, swearing.

If the construction company dealt with similar requirements electronically, downtime would be avoided - with a few clicks on the mobile phone, the worker informs about the missing sand and the preparer takes care of it right away.

Our experience shows that by digitizing requirements, recording tools or attendance, a construction company can save at least 10% of costs during construction. And you save another 10% on administration. Simply put, you will stop turning, searching and registering papers, everything will be in the system, it will go faster and you will have time to coordinate constructions or other and much more interesting work.

Or watch the recording of the webinar, in which its founder Josef Beneš explains the benefits and use of Stavario.

Builders who use Stavario repeatedly tell us that the digitization of the routine agenda has saved them exactly the percentages they are missing due to rising costs.

All you need is a computer, a mobile phone, a simple application and precise rules, how to:

- record attendance

- make demands on the construction site

- hand over tools